CHETRA thermosiphon system provides leakage compensation and cooling of the mechanical seal.

Circulation is by the thermosiphon principle or forced circulation by means of a circulation pump or conveyor system.

Level and pressure monitoring (Plan 53A) prevents dry running and monitors (product) leakage.

Versions:

The CHETRA thermosiphon system provides leakage compensation and cooling of the mechanical seal.

Circulation is by the thermosiphon principle or forced circulation by means of a circulation pump or conveyor system.

Level and pressure monitoring (Plan 53A) prevents dry running and monitors (product) leakage.

Suitable for oil & gas, petrochemical industry, chemical industry and refinery.

Versions:

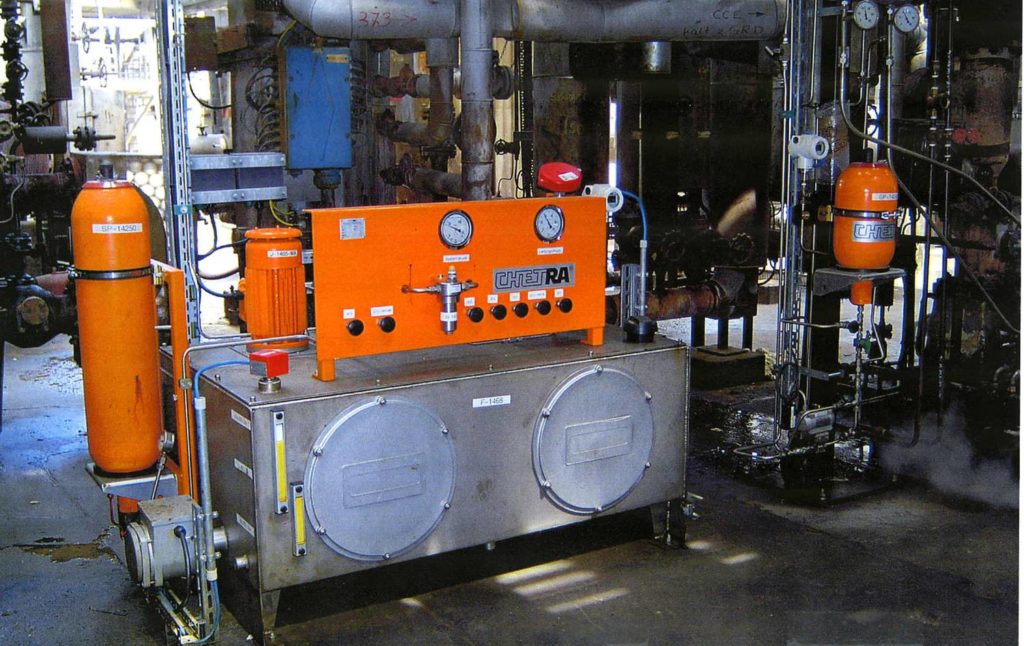

The CHETRA Loop System ensures permanent pressure superposition of double-acting mechanical seals. A pre-tensioned bubble accumulator provides the pressure in the sealing medium as well as leakage compensation.

The cooling of the sealing medium is done by finned tube or water tube coolers. The continuous pressure and temperature monitoring by modern measuring technology guarantees an improvement of the service life.

Especially suitable for oil & gas, petrochemical industry, chemical industry and refinery.

The CHETRA loop systems are TA-Luft compliant.

Versions:

The CHETRA pressure intensifier ensures the permanent pressure superimposition of double-acting mechanical seals even at very high pressures.

The automatic adjustment of the sealing pressure is done by a pulse line. This also compensates for larger pressure fluctuations.

Cooling of the sealing medium is done by finned tube coolers or water coolers. The constant pressure and temperature monitoring by modern measuring technology guarantees an improvement of the service life.

Especially suitable for oil & gas, petrochemical industry, chemical industry and refinery.

The CHETRA pressure intensifier is TA-Luft compliant.

Versions:

With the CHETRA quench tank, single-acting mechanical seals can be operated dead-ended. A suitable quench medium prevents the product from escaping to the atmosphere.

Level monitoring by level switch and sight glasses.

Versions:

Customized material combinations, instrumentation and designs specifically according to customer requirements can be developed by our qualified technical personnel.

The CHETRA leak detection system is used to collect leakage from the mechanical seal.

The amount of leakage is monitored by a level transmitter.

Especially suitable for oil & gas, petrochemical industry, chemical industry and refinery.

Versions:

Up to 25 loop systems can be supplied with the replenishment unit type 600LS.

Complete remote monitoring by pressure transmitter and level switch.

The replenishment is completely automatic. Automatic ball valves are installed on the loop systems and open when the pressure drops. The replenishment unit pumps barrier medium from a 600L unpressurized tank into the make-up lines. These are kept at a constant pressure by a bubble accumulator. In the event of a pressure drop in the makeup lines, e.g. due to increased makeup at the loop systems, one of the pumps automatically switches on and fills the makeup system until the specified pressure is built up again in the lines.

API Plan 54 – on request

Marsstraße 1

85551 Heimstetten b. München

Germany

Phone: +49 (0)89 32 94 64 – 0

Fax: +49 (0)89 32 94 64 – 20

Email: chetra@chetra.de

Schreiben Sie uns auf WhatsApp!